Erro de formato de e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

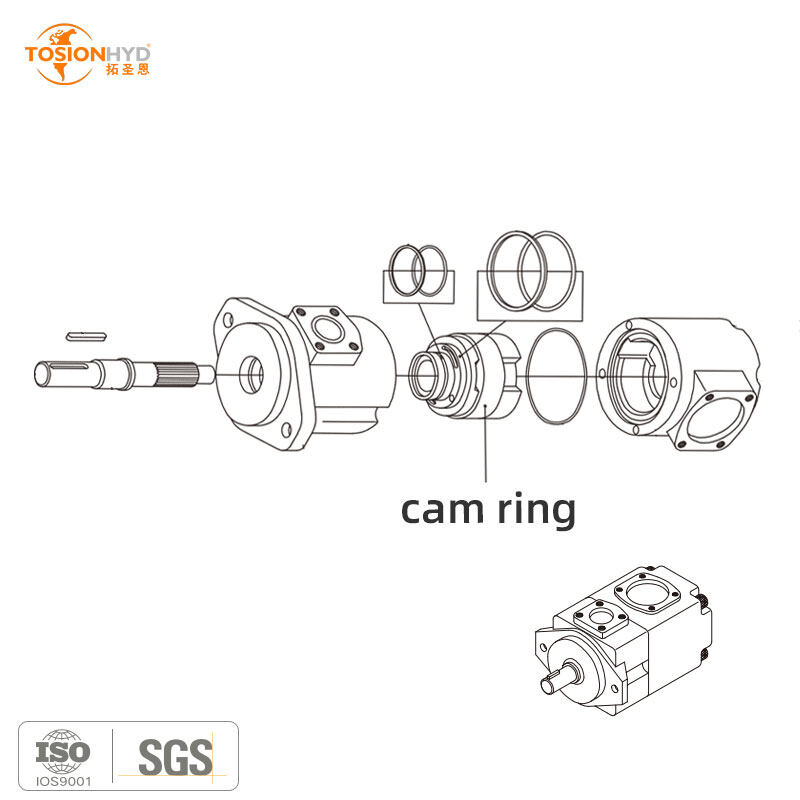

The cam ring is a circular ring with a series of lobes or cams on its inner surface that interact with the pistons to create the pumping action. The shape and size of the cams determine the flow rate and pressure of the pump. The cam rings are made of high-strength materials such as steel or bronze to withstand the high pressures and forces involved in hydraulic pumping.

Cam Ring Features:

[High-strength Material]:

Cam rings are crafted from tough materials like steel or bronze to endure the intense pressures and forces that come with hydraulic pumping. This ensures that they can handle the job without breaking a sweat.

[Precision Machining]:

The cam rings are machined with precision to guarantee reliable and consistent performance. This means that you can count on them to work smoothly and efficiently every time.

[Cams or Lobes]:

The inside of the cam ring has a bunch of bumps or lobes that work together with the pistons to make the pumping happen.

[Flow Rate and Pressure]:

The way the cams are shaped and how big they are decides how fast the liquid flows and how much pressure the pump can make.

[Durability]:

Cam rings are built tough and made to last, even when they’re used a lot and put through a lot of wear and tear.

[Compatibility]:

Cam rings are made to work with certain hydraulic pumps, so they fit just right and work the way they’re supposed to.

[Easy Replacement]:

If the cam ring gets worn out or damaged, it’s no big deal - you can just swap it out for a new one. It’s an easy and affordable way to fix the pump and get it back up and running.

Cam Ring Advantages:

[Efficient Pumping]:

The cam rings are made to make the pumping action smooth and efficient, which means you get a lot of liquid flowing through and a lot of pressure building up.

[Precise Control]:

By carefully designing the shape and size of the cams on the cam ring, you can have really precise control over how much liquid flows through the hydraulic pump and how much pressure it creates.

[Durability]:

Cam rings are usually built with really strong materials, so they can handle all the intense pressure and force that comes with hydraulic pumping. That means they’re tough and can last a long time.

[Smooth Operation]:

Cam rings make the pumping action really smooth and steady, which means there’s less wear and tear on the hydraulic pump and other parts.